What Are the Key Factors in Selecting HDP Color Steel for Building Facades?

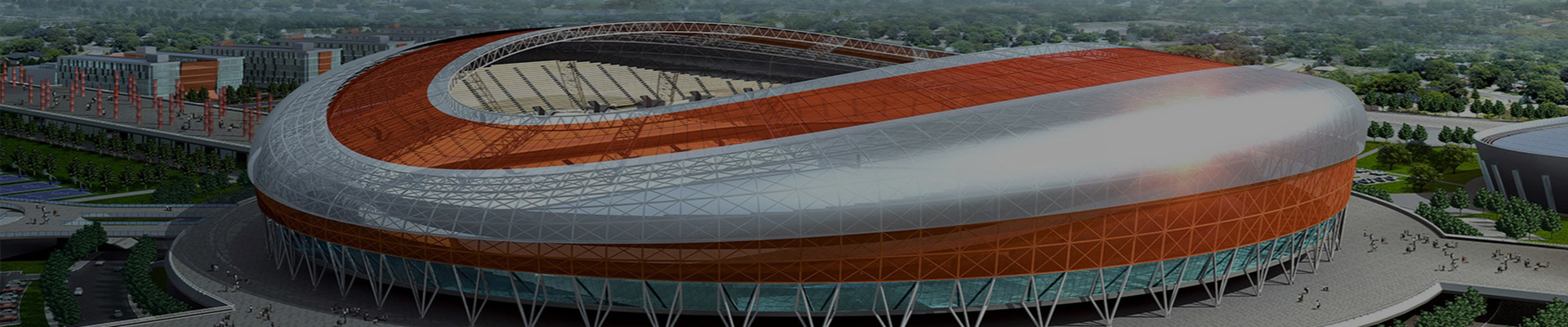

What are the key factors in selecting HDP color steel for building facades? Choosing the right facade material is essential for achieving durability, aesthetics, and long-term performance. HDP (High-Durability Polyester) color steel has become a popular choice for modern building facades due to its balanced performance, cost efficiency, and design flexibility. Understanding the key selection factors helps ensure optimal results for architectural projects.

1. Weather Resistance and Climate Conditions

One of the most important factors is the local climate. HDP color steel offers enhanced resistance to ultraviolet radiation, temperature fluctuations, and general weather exposure compared to standard polyester coatings. It performs well in most urban and industrial environments, making it suitable for building facades exposed to sunlight, rain, and moderate pollution.

2. Corrosion Resistance Requirements

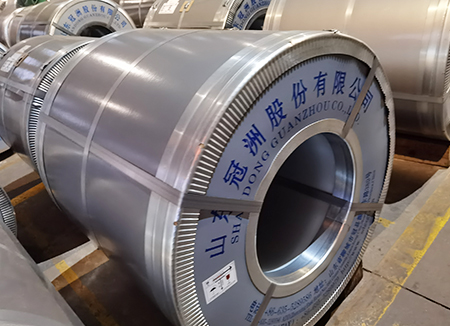

Facade materials must protect the building structure from corrosion over long periods. When selecting HDP color steel, factors such as substrate type (galvanized or galvalume steel), coating thickness, and environmental exposure should be considered. Proper corrosion protection ensures stable performance and extends the service life of the facade system.

3. Color Stability and Aesthetic Performance

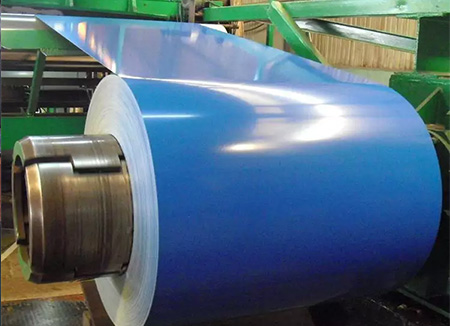

Color consistency and long-term appearance are critical for building facades. HDP coatings provide better color retention and reduced chalking compared to conventional polyester coatings. A wide range of colors and surface finishes allows architects to achieve desired visual effects while maintaining a clean and professional appearance over time.

4. Mechanical Strength and Formability

Building facades often require materials that can withstand wind loads, impacts, and installation stress. HDP color steel offers good mechanical strength, scratch resistance, and balanced flexibility. This combination allows for bending, profiling, and complex facade designs without compromising coating integrity.

5. Maintenance and Life-Cycle Cost

Long-term maintenance is a key consideration in facade material selection. HDP color steel requires less frequent cleaning and maintenance than lower-grade coatings. Its durability helps reduce repainting or replacement costs, resulting in lower life-cycle costs and improved cost efficiency for building owners.

6. Compliance with Building Standards and Certifications

HDP color steel used for building facades should comply with relevant building codes, quality standards, and sustainability requirements. Certifications related to quality management, environmental performance, and material safety add value and ensure reliable performance throughout the building’s lifespan.

7. Balance Between Performance and Budget

While PVDF coatings offer the highest level of durability, they may exceed project budget requirements. HDP color steel provides a practical balance between performance and cost, making it an ideal solution for commercial, industrial, and residential facade applications that require long-lasting performance without premium pricing.

Conclusion

Selecting HDP color steel for building facades involves evaluating climate conditions, corrosion resistance, aesthetic needs, mechanical performance, maintenance requirements, and budget constraints. By carefully considering these key factors, HDP color steel can deliver durable, visually appealing, and cost-effective facade solutions that meet modern architectural and performance demands.

-

2025-04-01

2025-04-01Analysis on the application fields and market trends of Xiaocao color coated coils

-

2025-04-01

2025-04-01Home appliance hardware colored steel plate: a solid barrier against daily wear and scratches

-

2025-04-01

2025-04-01How can color-coated plate wholesalers seize the opportunity of new infrastructure construction and expand their market share?

-

2025-04-01

2025-04-01The core role of home appliance hardware color steel plate in intelligent home appliances