How Does PE Polyester Coating Protect Indoor Metal Panels?

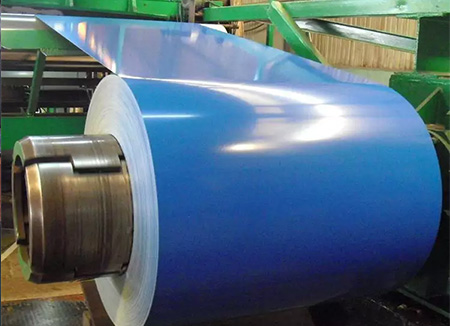

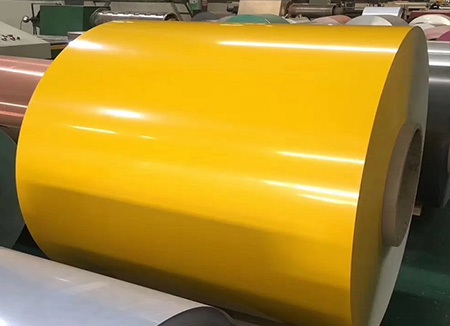

How does PE polyester coating protect indoor metal panels? PE (Polyester) coating is one of the most commonly used surface treatments for color coated steel, especially in indoor applications. While it is not designed for extreme outdoor exposure, PE coating provides reliable protection, aesthetic value, and cost efficiency for indoor metal panels when applied in suitable environments.

1. Basic Corrosion Protection in Controlled Environments

Indoor spaces generally have stable temperature and low exposure to moisture, UV radiation, and pollutants. PE polyester coating forms a uniform protective film on the metal surface, effectively isolating the substrate from air and minor humidity. This barrier helps prevent oxidation and corrosion, ensuring the metal panels remain structurally sound in indoor conditions.

2. Smooth Surface and Decorative Appearance

PE coatings offer excellent color consistency and surface smoothness. For indoor metal panels used in ceilings, partitions, wall cladding, or decorative systems, PE coating provides a clean and attractive appearance. A wide range of colors and finishes allows designers to meet functional and aesthetic requirements without additional surface treatments.

3. Good Adhesion and Formability

PE polyester coating demonstrates strong adhesion to metal substrates, which helps maintain coating integrity during fabrication and installation. Its good flexibility allows metal panels to be bent, formed, or cut without cracking or peeling. This is especially important for indoor applications that require precise shaping and customized panel designs.

4. Resistance to Minor Wear and Cleaning

Indoor metal panels may be subject to light contact, routine cleaning, and occasional abrasion. PE coatings provide sufficient surface hardness to resist minor scratches and wear under normal indoor use. The coated surface is also easy to clean, helping maintain hygiene and appearance in commercial and public indoor spaces.

5. Cost-Effective and Efficient Solution

Compared to higher-performance coatings such as SMP, HDP, or PVDF, PE polyester coating is more economical. For indoor applications where environmental exposure is limited, PE coating delivers adequate protection at a lower cost. This makes it an efficient choice for large-scale interior projects with controlled conditions.

6. Compatibility with Indoor Building Standards

PE-coated metal panels are commonly used in compliance with indoor building standards related to safety, appearance, and material performance. When properly specified, they meet functional requirements for interior environments without unnecessary over-engineering.

Conclusion

PE polyester coating protects indoor metal panels by providing basic corrosion resistance, strong adhesion, good formability, and an attractive finish in controlled environments. Its cost efficiency and reliable performance make PE coating a practical and widely used solution for indoor metal panel applications, where durability needs are moderate and environmental exposure is limited.

-

2025-04-01

2025-04-01How can the color steel coil slitting industry adapt to the diversified market needs?

-

2026-01-10

2026-01-10What Innovations Are Extending PVDF Color Plate Lifespans?

-

2025-04-01

2025-04-01How can color-coated plate wholesalers seize the opportunity of new infrastructure construction and expand their market share?

-

2025-04-01

2025-04-01Home appliance hardware color steel plate: key material to improve the durability of home appliance products