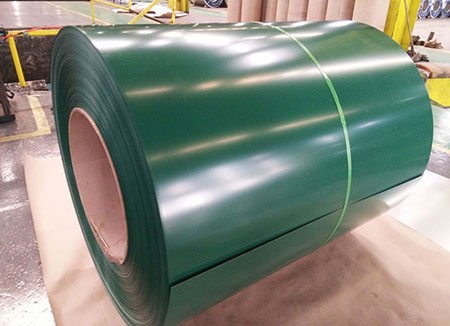

What Are the Key Sustainability Certifications for Color Coated Steel?

What are the key sustainability certifications for color coated steel? As sustainability becomes a central focus in the global construction and manufacturing industries, certifications play an essential role in verifying the environmental performance of building materials. For color coated steel, recognized sustainability certifications provide assurance of responsible production, environmental compliance, and long-term value for green building projects.

1. ISO 14001 Environmental Management System

ISO 14001 is one of the most important international certifications related to environmental management. It confirms that manufacturers of color coated steel have implemented effective systems to control environmental impact, reduce waste, and improve resource efficiency. This certification demonstrates a company’s commitment to continuous environmental improvement throughout the production process.

2. ISO 9001 Quality Management System

Although primarily focused on quality, ISO 9001 indirectly supports sustainability by ensuring consistent production processes, reduced defects, and efficient use of raw materials. For color coated steel, ISO 9001 certification indicates reliable quality control, which helps extend product lifespan and reduces unnecessary material waste.

3. Environmental Product Declaration (EPD)

An Environmental Product Declaration provides transparent, third-party verified data on the environmental impact of a product throughout its life cycle. For color coated steel, an EPD typically includes information on carbon footprint, energy consumption, water usage, and recyclability. EPDs are widely recognized in green building standards and support informed decision-making for sustainable construction.

4. LEED Contribution and Compliance

While LEED (Leadership in Energy and Environmental Design) is a building-level certification, color coated steel products can contribute to earning LEED credits. Features such as recycled content, durability, energy-efficient coatings, and verified EPDs help projects meet LEED sustainability requirements. Using certified color coated steel supports green building performance and regulatory compliance.

5. ResponsibleSteel Certification

ResponsibleSteel is a global sustainability standard specifically designed for the steel industry. It addresses environmental stewardship, climate action, human rights, and ethical business practices. Color coated steel produced by ResponsibleSteel-certified manufacturers demonstrates compliance with strict sustainability, safety, and social responsibility criteria.

6. RoHS Compliance

RoHS (Restriction of Hazardous Substances) compliance ensures that color coated steel coatings and surface treatments do not contain harmful substances above regulated limits. This certification is particularly important for projects that prioritize environmental health, indoor air quality, and safe material use.

7. REACH Regulation Compliance

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) is a European Union regulation that controls the use of chemical substances. Color coated steel that complies with REACH standards ensures that coatings and production materials are safe for both human health and the environment, supporting sustainable and responsible manufacturing.

Conclusion

Understanding the key sustainability certifications for color coated steel is essential for making environmentally responsible material choices. Certifications such as ISO 14001, EPD, ResponsibleSteel, and compliance with LEED, RoHS, and REACH standards provide clear evidence of sustainability performance. By selecting certified color coated steel, builders and developers can enhance environmental credibility, meet green building requirements, and support a more sustainable construction industry.

-

2026-01-17

2026-01-17How Does HDP Coating Extend the Life of Color Steel?

-

2025-04-01

2025-04-01Home appliance hardware color steel plate: key material to improve the durability of home appliance products

-

2025-04-01

2025-04-01Exploring the production process of PE polyester color-coated sheets: revealing the source of quality

-

2026-01-31

2026-01-31Is Automation Changing Production Efficiency for PE Polyester Boards?