-

2026-01-31

2026-01-31Is Automation Changing Production Efficiency for PE Polyester Boards?

-

2026-01-31

2026-01-31How Does PE Polyester Coating Protect Indoor Metal Panels?

-

2026-01-24

2026-01-24How Do Climate-Specific Standards Impact SMP Coating Performance?

-

2026-01-24

2026-01-24What Makes SMP a Reliable Choice for Industrial Building Exteriors?

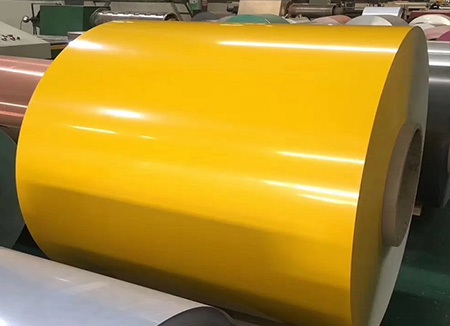

Hot dip galvanized strip steel

-

Product Description

In order to ensure the stability of the rolling process, lotion cleaning must be used, because it can not only reduce the rolling force, but also improve the surface quality of hot-dip galvanized strip steel. The surface residue of strip steel is closely related to the characteristics of emulsion.

In order to ensure the use of lotion, additives need to be added to improve the performance, so that lubricant molecules can form one or several layers of adsorption film with network structure formed by * molecules on the metal surface, and base oil molecules are dissolved in this network structure. The adsorption membrane has certain toughness and compressive strength, which can effectively prevent direct contact of micro protrusions on the metal surface, prevent adhesion, and reduce friction.

Hot dip galvanized strip steel

Due to the strong adsorption force between the * molecules in the emulsion and the metal surface, additives improve the rolling performance of the emulsion, ensuring the stability of rolling. On the other hand, the * molecules in the additives, along with impurities such as oily components, fine iron powder, and leaked impurities from the rolling mill hydraulic system in the emulsion, stably exist in the uneven areas of the steel plate surface through the strong * (adsorption) effect of the * molecules.

According to the cleaning principle, dirt must go through the process of wetting, soaking, wrapping, and peeling with cleaning agents before it can be removed from the surface of the steel plate. The strong action of * molecules precisely affects the progress of the above cleaning process, resulting in a decrease in cleaning efficiency.

-

Specifications